350mm Graphite Electrode made in China The main uses of graphite electrode are as follows: (1) For EAF Graphite electrode is mainly used in electric furnace steelmaking. Electric furnace steelmaking is to use graphite electrode to introduce current into the furnace. Strong current generates arc discharge through gas at the lower end of the electrode, and uses the heat generated by the arc to smelt. According to the capacity of the electric furnace, graphite electrodes with different diameters are used. In order to make the electrodes continuously used, the electrodes are connected by threaded joints. The amount of graphite electrode used in steelmaking is about 70-80% of the total amount of graphite electrode. (2) For submerged arc furnace Graphite electrode submerged arc furnace is mainly used to produce ferroalloy, pure silicon, yellow phosphorus, matte, calcium carbide, etc. its feature is that the lower part of the conductive electrode is buried in the furnace charge. Therefore, in addition to the heat generated by the electric arc between the electric plate and the furnace charge, the heat is also generated by the resistance of the furnace charge when the current passes through the furnace charge. The consumption of graphite electrode is about 150kg per ton of silicon and 40kg per ton of yellow phosphorus. (3) For resistance furnace The graphitization furnace for the production of graphite products, the melting furnace for the melting of glass and the electric furnace for the production of silicon carbide are all resistance furnaces. The materials in the furnace are both the heating resistance and the heated object. Generally, the graphite electrode for conducting is inserted into the furnace head wall at the end of the furnace bed, so the conducting electrode is not consumed continuously. In addition, a large number of graphite electrode blanks are also used to process various kinds of special-shaped products such as crucible, graphite boat dish, hot die casting mold and heating body of vacuum electric furnace. For example, in the quartz glass industry, 10t graphite electrode blank is required for each production of LT electric melting tube, and 100kg electrode blank is consumed for each production of LT quartz brick. What is a common power graphite electrode? The current density of the graphite electrode used in the high power and ultra-high power electric furnaces increases obviously, resulting in the following problems: (1) the temperature of the electrode increases due to the hot resistance and hot air flow, which increases the thermal expansion of the electrode and the joint, and the oxidation consumption of the electrode also increases R (2) the temperature difference between the center of the electrode and the outer circle of the electrode increases, and the thermal stress caused by the temperature difference also increases accordingly, The electrode is easy to produce cracks and surface peeling; (3) the increase of furnace power leads to the increase of electromagnetic force, which causes violent vibration and the increase of the probability of electrode breaking. Therefore, the physical and chemical properties of high-power and ultra-high-power graphite electrode must be better than that of ordinary power graphite electrode, For example, low resistivity, high density, high mechanical strength, small coefficient of linear expansion, excellent oxidation resistance and thermal shock resistance can meet the requirements of high power and ultra-high power electric furnaces350mm Graphite Electrode made in China website:http://www.graphite-electrode-products.com/350mm-graphite-electrode/

Procurar

Assuntos do momento

-

Technological Advancements in Pipeline Integrity: Market Analysis and Forecast, 2030

-

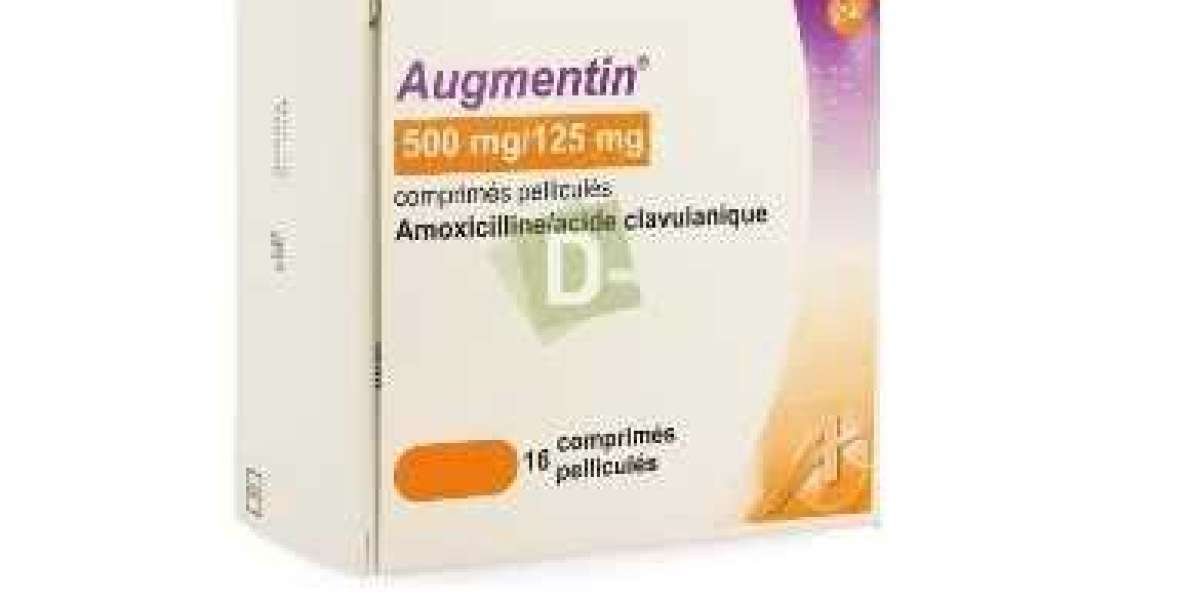

The pros And Cons Of Pharmacies Shipping To Usa

The pros And Cons Of Pharmacies Shipping To Usa

-

Elevate Your Creative Expression with the Best 3D Pens Near Me - WOL3D Coimbatore

Elevate Your Creative Expression with the Best 3D Pens Near Me - WOL3D Coimbatore

-

Elevate Your Prints with 3D Printer PLA Filament Online - WOL3D Coimbatore

Elevate Your Prints with 3D Printer PLA Filament Online - WOL3D Coimbatore

-

Stay Cool and Comfortable with Gree Malta Air Conditioners| DL Group

Stay Cool and Comfortable with Gree Malta Air Conditioners| DL Group