Cross docking, a logistics strategy where goods are transferred directly from inbound to outbound transportation with minimal storage, has become a crucial element in today's fast-paced supply chain. However, with the ever-increasing demand for speed and efficiency, traditional cross-docking methods are reaching their limitations. This is where cross docking automation comes in, leveraging advanced technologies to streamline and enhance the process, offering significant benefits for businesses and consumers alike.

Understanding Cross Docking:

At its core, cross docking eliminates the need for extensive storage by strategically sorting and routing incoming goods directly to awaiting outbound shipments. This reduces handling costs, optimizes space utilization, and accelerates delivery times. It's particularly beneficial for time-sensitive products like perishables, electronics, and pharmaceuticals.

Challenges of Traditional Cross Docking:

While offering several advantages, traditional cross-docking faces challenges:

- Labor Intensity: Manual sorting and routing of goods can be labor-intensive, prone to errors, and struggle to scale with increasing volumes.

- Limited Scalability: Traditional methods are often inflexible and struggle to adapt to fluctuating demand or product variations.

- Safety Concerns: Manual handling of goods, especially heavy items, can lead to safety hazards and injuries for workers.

Revolutionizing the Process: Automation in Cross Docking

Cross-docking automation addresses these challenges by integrating various technologies, transforming the process into a highly efficient and dynamic system. Here's how:

- Automated Sorting Systems: Conveyor belts equipped with barcode scanners and sorting mechanisms efficiently segregate goods based on their destination and characteristics, minimizing manual intervention.

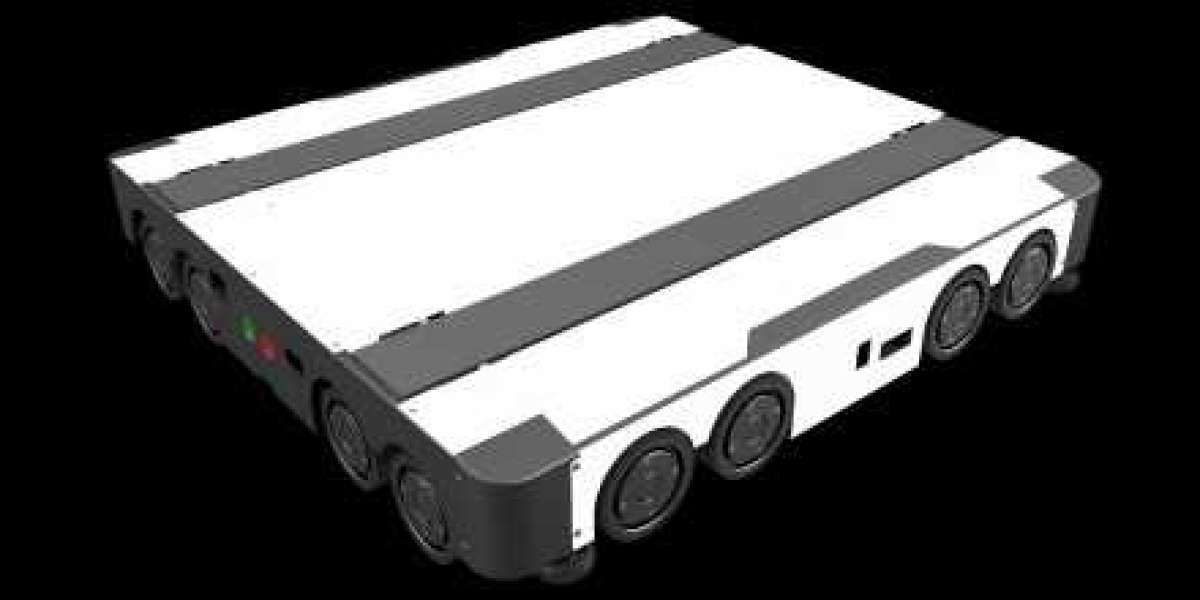

- Autonomous Mobile Robots (AMRs): These intelligent robots navigate the warehouse autonomously, transporting goods between receiving docks, sorting areas, and loading bays, increasing flexibility and reducing reliance on fixed infrastructure.

- Warehouse Management Systems (WMS): These software solutions act as the brains of the operation, receiving real-time data on inventory levels, orders, and resource availability. They optimize workflows, guide automation processes, and ensure accurate order fulfillment.

- Robotics for Palletizing and Depalletizing: Robots can efficiently palletize and depalletize goods, reducing manual effort and ensuring consistent, safe handling of even heavy items.

Benefits of Cross Docking Automation:

Implementing cross-docking automation unlocks a range of benefits:

- Increased Efficiency: Automation significantly reduces manual sorting and handling, leading to faster throughput and shorter order fulfillment times.

- Enhanced Accuracy: Automation minimizes human error in sorting and routing, ensuring accurate order fulfillment and reducing product damage.

- Improved Scalability: Automated systems can easily adapt to fluctuating demand or product variations, providing greater flexibility and scalability for businesses.

- Reduced Costs: Automation helps streamline operations, leading to lower labor costs, improved space utilization, and potentially reduced storage requirements.

- Enhanced Safety: By minimizing manual handling, automation significantly reduces the risk of workplace injuries.

Considerations for Implementing Cross-Docking Automation:

While highly beneficial, certain factors need to be considered before implementing cross-docking automation:

- Cost-Benefit Analysis: Evaluating the initial investment in technology and infrastructure compared to the potential return on investment (ROI) is crucial.

- Warehouse Layout and Design: Existing warehouse layouts might require modifications to accommodate automated systems.

- Integration with Existing Systems: Ensuring seamless integration of automation with existing WMS and other systems is vital for smooth operation.

Conclusion:

Cross-docking automation represents a significant advancement in supply chain efficiency, offering businesses a competitive edge in today's demanding market. By leveraging the power of automation, companies can achieve faster delivery times, reduce costs, and enhance customer satisfaction while ensuring a safer work environment for their employees. As technology continues to evolve, we can expect even more innovative solutions to emerge, further revolutionizing the future of cross-docking and the entire supply chain landscape. Visit the official website of rainbow-dynamics